iPhone 12 skin

I’m not a fan of bulky phone cases, so instead of opting for those, I came across dbrand skins. However, at 25 euros, I’d rather customize my own and save some money. Here’s how I created my custom iPhone 12 skin:

Step 1: Get template iPhone

After searching fot .svg or .dxf iPhone templates on the internet i only could find payed options, so I searched for CAD file of an iPhone 12.

- Download the iPhone 12 model from

GrabCAD

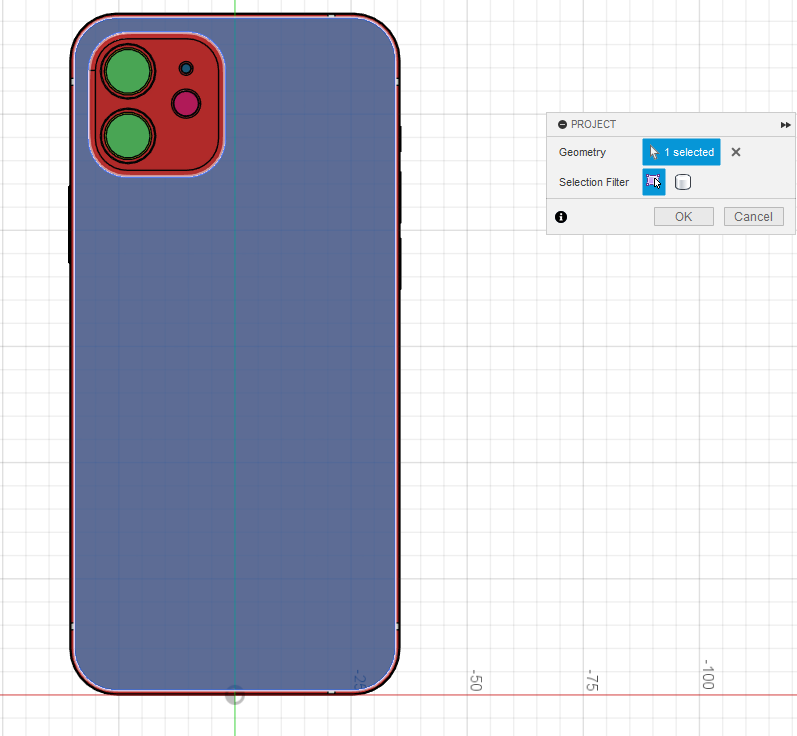

I use this model to get the template of the back of the Iphone 12 in Fusion 360

- Open the downloaded file in Fusion

- Create sketch on the back of the iPhone and project only the glass

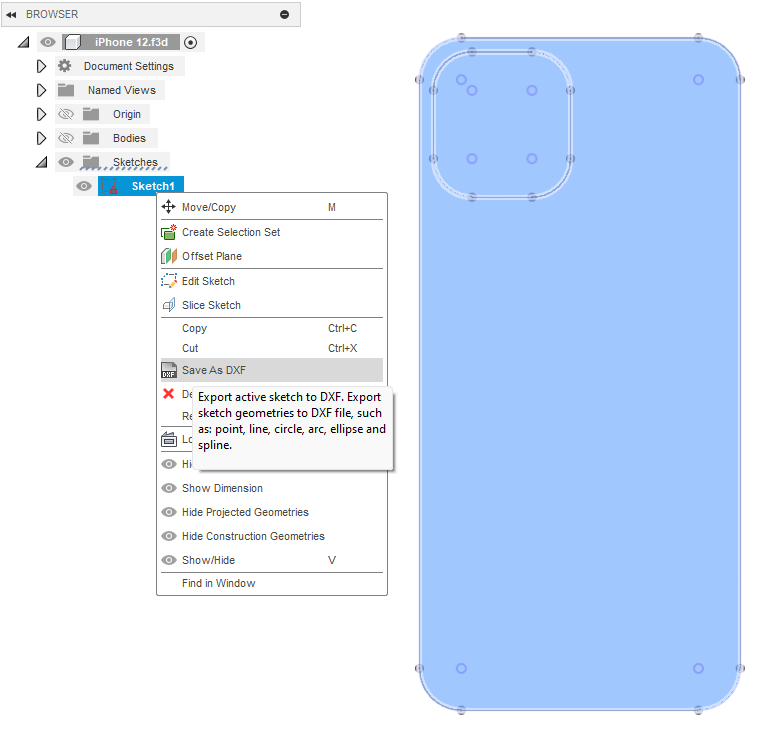

Figure 1 - Export the sketch as a

.dxfFigure 2

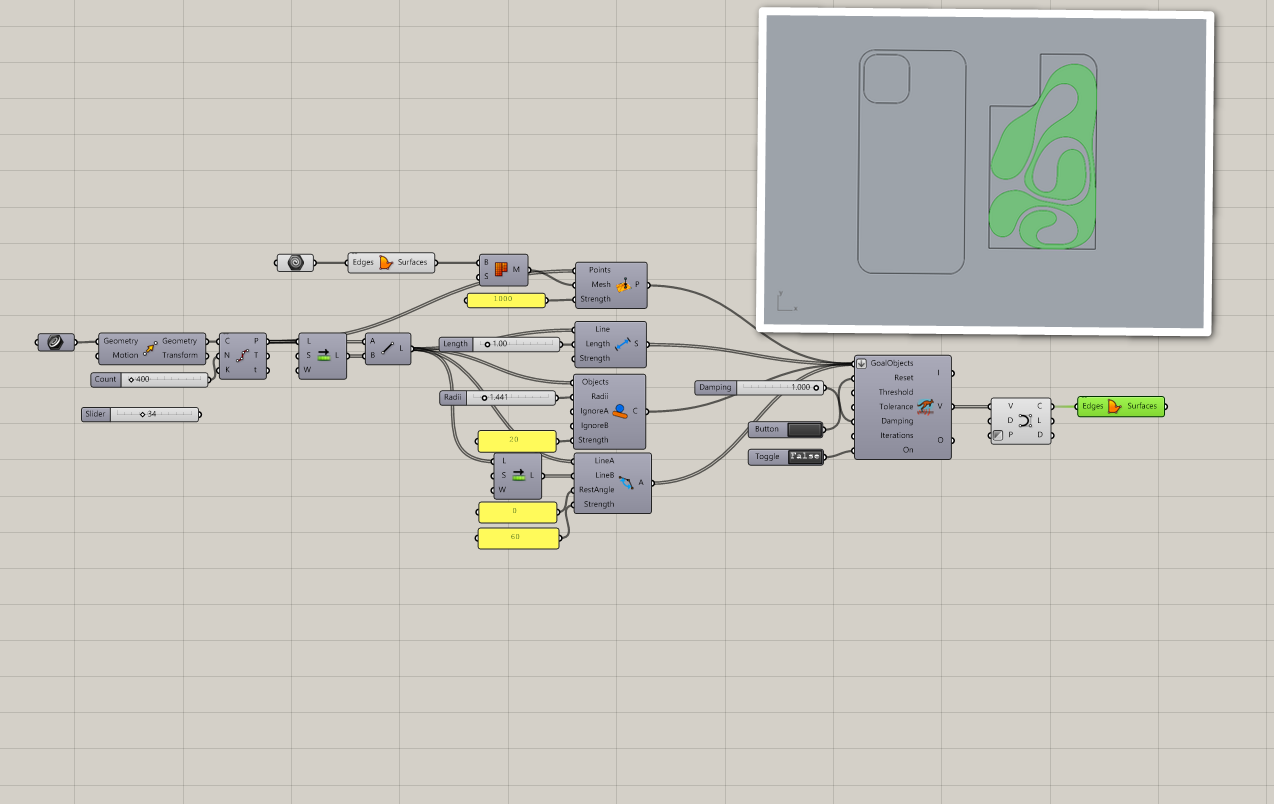

Step 2: Costom design in Rhino Grasshoper

While making this skin i’m following a minor course at the RobotLab where I used this tutorial about thalluses to create a drawing. I will use this to create the design on the skin.

-

Watch

thistutorial on YouTube from “The Different Design” -

Install the pluging

Kangaroo2fromfood4Rhino -

Download my 2 files or follow

Figure 3

Download .3dm File Download .gh File

As you can see you can change the bounary box if you till want to fit text underith

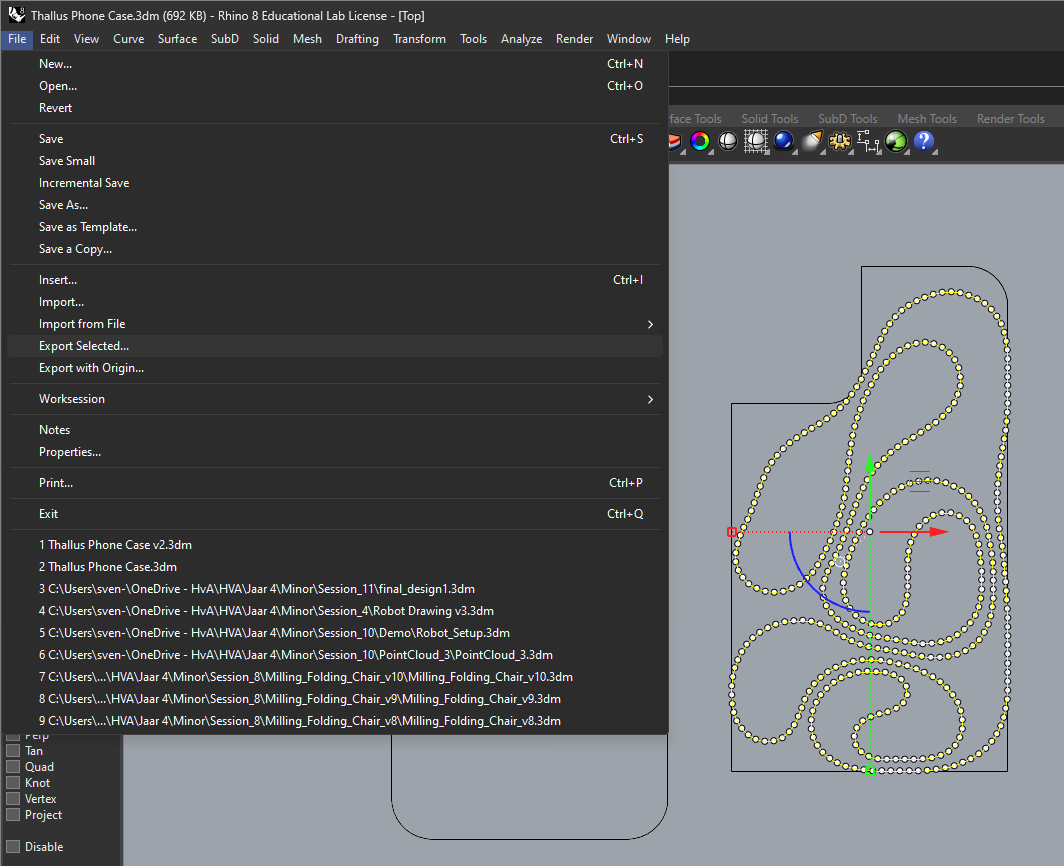

- Bake the last node in grasshoper and sellect it in Rhino

- Sellect the curve you just baked in Rhino and go to

Filein the upper right corner and in the drop down menu sellectExport Sellected... - In the next menu you want to save it as an

.dxf

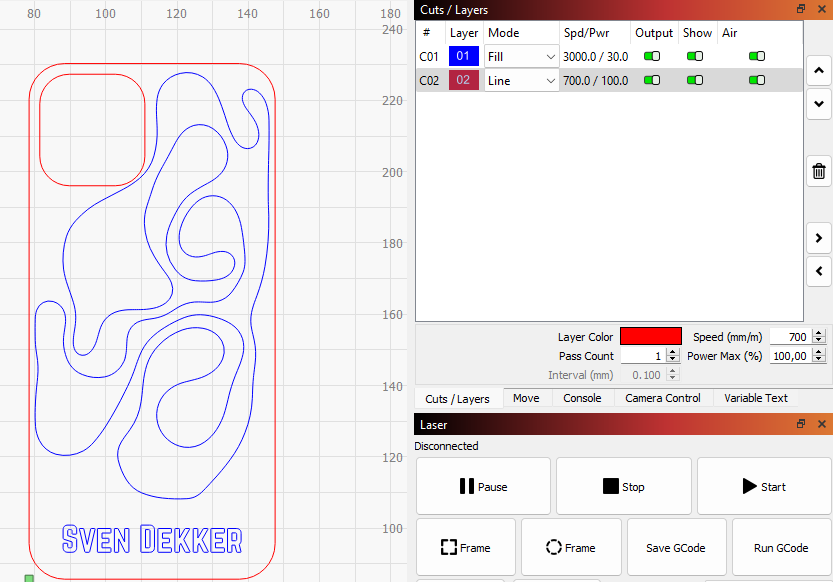

Step 3: Impored in LightBurn

LightBurn is a laser cutting and engraving software I use for my laser cutter. Iam going to combine the two .dxf files and at text and that is what im evaltualy going to laser cut and engrave.

- Import the two

.dxfinto LightBurn - Alline and scale them as you like

- At text underneath

- Devide the part into two layers.

- Layer 1: Line

- Layer 2: Fill

It should look something like Figure 5

For the correct engraving and laser cut setting you should do some small experiment for you!

Step 4: Engraving and Laser Cutting

When your happy with the design and the settings are correct you can send it to the lasercutter. I have a small clip of the process

Result